The Transformation of Semiconductor Testing with AI

AI in Semiconductor Testing: The Future of Smarter, Faster, and More Efficient Tests

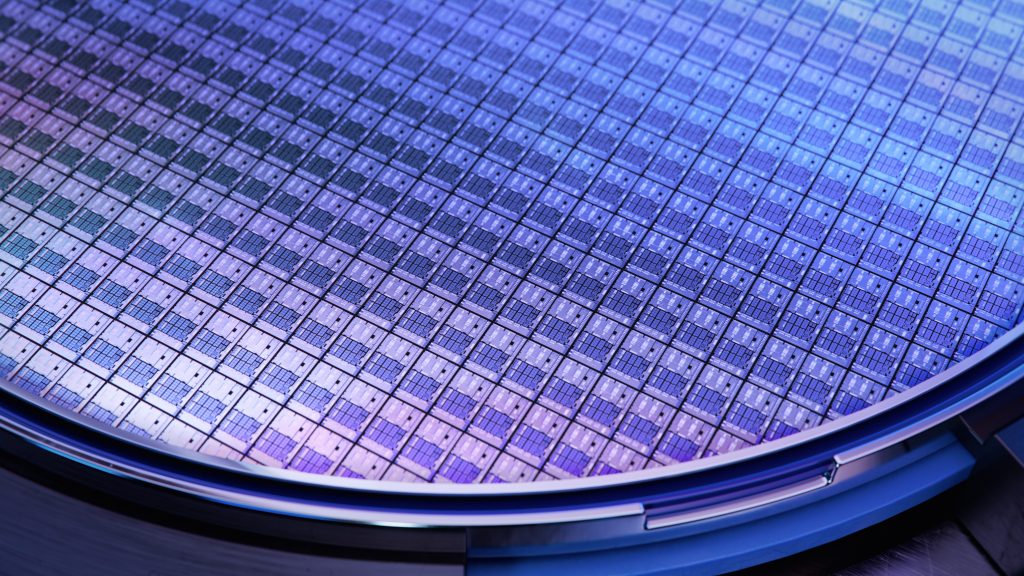

As semiconductor technology continues to evolve, the need for faster, more accurate, and cost-effective testing grows. Artificial Intelligence (AI) is revolutionizing semiconductor testing by automating processes, improving defect detection, and increasing overall efficiency.

Key Benefits of AI in Semiconductor Testing

AI-powered Defect Detection and Classification

AI-driven computer vision enhances wafer inspection by detecting subtle defects that traditional methods often miss. Machine learning models provide:

- Faster and more accurate defect classification – AI can process vast amounts of image data in real time and identify microscopic defects with greater precision than manual inspection methods.

- Reduction of false positives and false negatives – Advanced AI algorithms enhance detection reliability, resulting in fewer unnecessary rejections and ensuring that defective chips do not go unnoticed.

- Higher precision in identifying yield-impacting issues – AI assists in detecting defects that significantly affect performance, enabling manufacturers to address problems proactively.

Intelligent Test Optimization

AI enables dynamic test adjustments, reducing unnecessary tests while maintaining reliability. With AI-driven optimization:

- Adaptive tests adjust test flows based on real-time data — AI analyzes incoming test results and modifies subsequent tests, focusing on critical areas instead of testing every chip fully.

- Shorter test times lead to lower operational costs — By eliminating redundant tests and streamlining procedures, manufacturers save time and resources.

- Higher throughput and improved efficiency — Faster test processes allow more chips to be processed in less time, increasing overall production capacity.

Predictive Analytics for Yield Improvement

AI uses historical data to predict potential defects before they occur. This proactive approach results in:

- Higher yields and less waste — Identifies factors affecting yield at an early stage, enabling process adjustments that improve overall output.

- Data-driven decision-making for process improvements — Provides actionable insights, enabling manufacturers to refine production parameters for maximum efficiency.

- Enhanced production efficiency — Predictive models detect and correct potential defects before they impact large batches of chips.

Real-time Anomaly Detection and Root Cause Analysis

AI continuously monitors production data to detect and analyze issues early. This leads to:

- Reduced downtime and improved process stability — detects anomalies in production processes, preventing minor issues from escalating into major failures.

- Early identification of process deviations and equipment failures — monitors production condition trends, enabling corrective actions before significant abnormalities occur.

- Faster root cause analysis and corrective actions — processes vast datasets at high speed to identify sources of failures, reducing troubleshooting time and minimizing production losses.

AI-driven Automation and Self-learning Systems

AI-powered semiconductor test systems can adapt and improve over time, resulting in:

- Automated decision-making and test adjustments — AI systems autonomously optimize test strategies based on previous results, increasing efficiency with minimal human intervention.

- Digital twin simulations for real-world performance analysis — AI-driven digital twins create virtual models of semiconductor components, allowing manufacturers to simulate and predict performance before physical testing.

- Lower operational costs with improved quality control — AI-driven automation reduces the need for manual labor, cuts costs, and simultaneously improves accuracy and consistency.

AI in Reliability Testing and Failure Prediction

By analyzing stress test data, AI helps predict the long-term reliability and durability of semiconductors, resulting in:

- Fewer early failures — Identifies potential weak points in chips, enabling defective units to be detected and corrected before deployment.

- Product lifetimes are extended — Helps manufacturers refine designs and materials to improve the lifespan and reliability of chips in real-world applications.

- More robust chip designs — AI-driven insights enable the development of stronger and more efficient semiconductor architectures, reducing long-term failure rates.

The Future of AI in Semiconductor Testing

AI is transforming semiconductor testing, making it more efficient, cost-effective, and accurate. As chip complexity increases, AI will play an even greater role in ensuring high yields, improving quality, and driving innovation in the semiconductor industry.